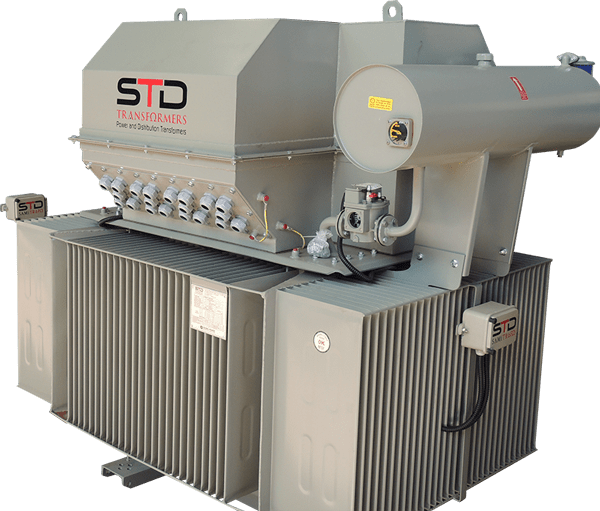

STD Transformers are manufactured to provide a high quality and reliable transformer to the end user. We are using Quality-Oriented Manufacturing (QMS) platform, which defines design standards, equipment and processes used in its facilities. Use of this Common Technology enables us to guarantee customers a high quality and consistent product.

The transformer is a static inductive device that can step the voltage up and down to transfer electrical power efficiently. Winding types and methods that offer the least loss were selected using magnetic field analysis, and also used in the STD Transformers to ensure high levels of efficiency.

Moreover, by selecting the optimal insulating structure through the electric field analysis of insulation between turns, sections, windings and phases, the Transformer’s electrical stability is achieved. STD fluent analysis technology has enabled the realization of an optimal cooling system, and 3 structure strength analysis has enabled a structural design that can withstand internal mechanical power short-circuits caused by system faults, seismic conditions according to external impacts, and the impact of transportation.”

Our factory is equipped with the latest core processor machines, the latest winding machines, highcapacity vacuum heat drying equipment, state-of-the-art cleaning facilities, and has the best test room.

Magnetic Core

Magnetic Core

The magnetic circuit is of column type with mitred joints. It is manufactured with first rate, grain oriented magnetic cold-rolled silicon steel lamination or amorphous steel. The mounted core is clamped down to reduce vibrations and minimize noise level. Further noise level and noload losses decreasing are achieved by step lap core construction

Insulating Liquids

The mineral oil both inhibited and uninhibited types with its electrical and chemical characteristics is in compliance with IEC standards and PCB and PCT free. On special requests other insulation fluids, such as silicon, synthetic ester or natural ester are available

Off-Circuit Tap Changer

The tappings of MV windings are connected to the off-circuit tap changer. The handle is located on the cover and should only be operated when the transformer is de-energized. The mechanism can also be pad-locked during normal operation.

LV & MV Windings

The windings are made of two components, conductor and the insulation materials. The conductors used are a high grade electrolytic copper or aluminum and are insulated with pure cellulose or double enamel. The MV windings are wound either with round, double enamel insulated or rectangular, paper insulated wire. The LV windings are wound with rectangular, paper insulated wire, enameled wire or foil.

Tank and Cover

Tank walls are made of corrugated cooling surfaces. The welds are tested for oil tightness. The complete tank is tested and approved acc. to Cenelec HD 428.6 S1 standard.

Painting and Surface Treatment

All metal parts are carefully sand-blasted and painted. Alternatively hot deep galvanized transformers can be supplied for use in heavy corrosion areas. Detailed painting procedures for different environmental conditions are available

Testing Process

All transformers are tested in our testroom according IEC 60076 standards. All transformers are delivered with maintenance manual, test report, technical drawing and all necessary certifications. STD Transformator has test room with very high level equipment. We are able to make all routine tests, without any exception. Our test room is equipped with a special converter 400 A up to 12000V with frequency ranging from 50 Hz up to 400 Hz. Furthermore there is an impluse test device, which guarantees impulse test range up to 400kV.

Routine Tests

- Measurement Of Winding Resistance

- Measurement Of Voltage Ratio And Check Of Phase Displacement

- Measurement Of Short-Circuit Impedance and Load Loss

- Measurement Of No-Load Loss and Current

- Dielectric Routine Tests (IEC 60076-3)

- Test On OLTC, Where Appropriate

- Leak Testing With Pressure For Liquid-Immersed Transformers

- Tightness Tests and Pressure Tests For Tanks For Gas-Filled Transformers

- Check of Ratio and Polarity of Build-in Current Transformers

- Check Core and Frame Insulation Transformers With Core Frame Insulation

Type Tests

- Temprerature Rise Type Test (IEC 60076-2)

- Dielectric Type Tests

- Determination of Sound Level For Each Method Of Cooling

- Measurement Of The Power Taken By Fan and Liquid Pump Motors

- Measurement Of No-Load Loss and Current at 90% and 110% of Rated Voltage

Special Tests

- Measurement of Zero-Sequence Impedances On Three-Phase Transformers

- Measurement of D.C. Insulation Resistance Each Winding Winding to Earth and Between Windings

- Determination of Weight with Transformer Arranged for Transport